DIY Polecat

We are frequently asked if we have any tips for making a do-it-yourself version of our Hicat® units so we've put together the following notes for making a DIY Polecat

The following notes & images are from our now out of date Fabrication Guide, which was developed for our partner manufacturing production so we've adapted these as instructions for this DIY project in terms of tools & techniques with the addition of some new photos where applicable.

A DIY Kit of standard parts, fixings & tools can be purchased using the link at the bottom of the page to help complete this DIY project.

The price of the DIY Kit is £24 - delivery is calculated at checkout & please get in touch if your country isn’t listed & we can provide a Delivery Quote.

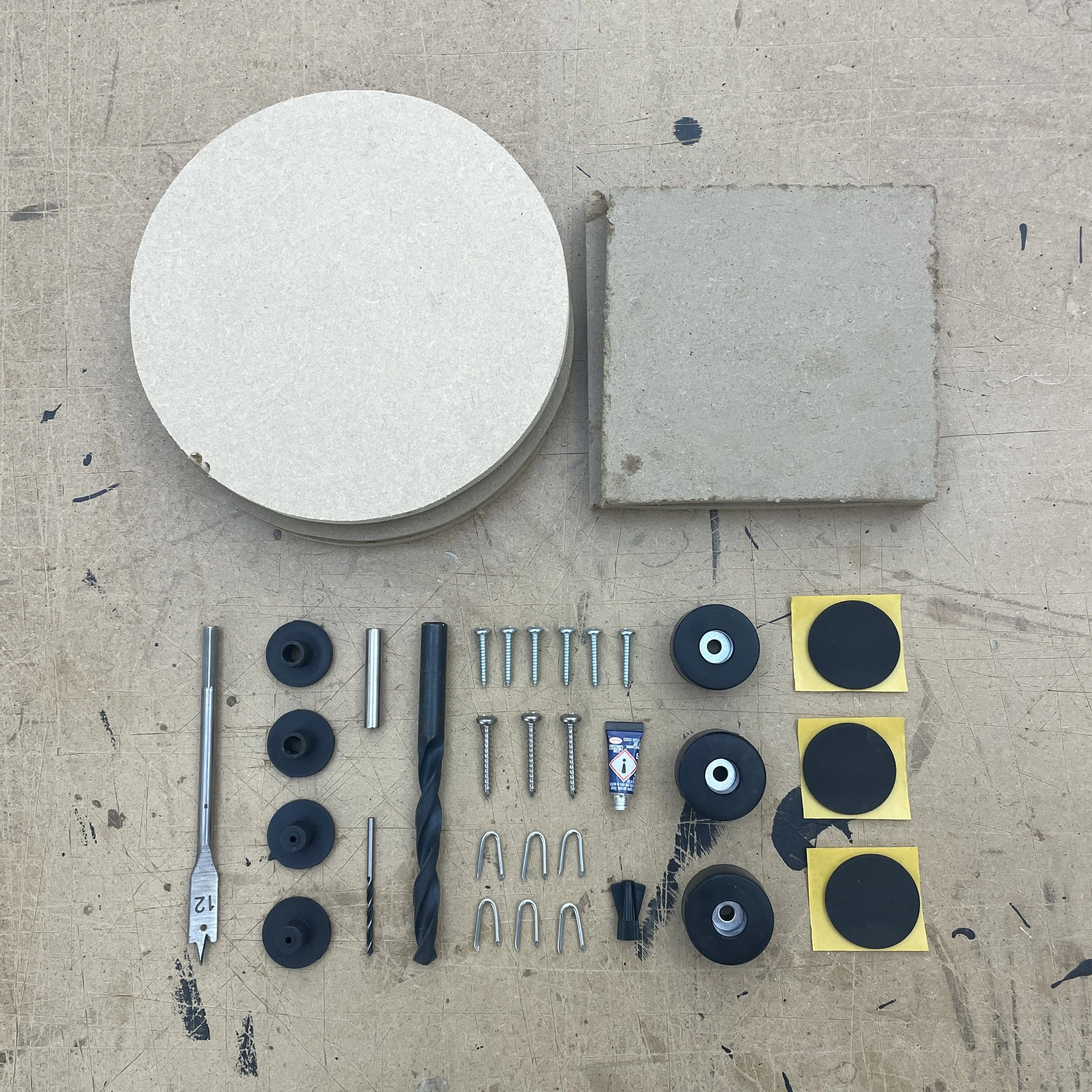

The DIY Kit includes the following parts for the fabrication & install - we've also listed the materials, tools & other bits that you will need to complete your DIY Polecat:

Fabrication

2 Bushes (Closed Ended)

6 Pan Head Screws

1 Flat Wood Bit

1 Spur Wood Bit

6 U-Nail Staples

6 MDF Off Cuts (2x 12mm & 4x 9mm)

Installation

3 Feet

3 Pan Head Screws

1 Ceiling Connector

2 Bushes (Open Ended)

1 Drill Bit

1 Glue Tube

3 Foam Pads

Construction Materials

Cardboard Tube (ceiling height minus 78mm)

Carpet (ceiling height plus 150mm & 3.3x outside tube diameter)

Carpet Glue (0.5-1L)

Hot Melt Glue Sticks (10 to 20 mini 7mm sticks or 2-4 standard size 12mm sticks)

Tools

Hot Melt Glue Gun

Tenon or Carpentry Saw

Jigsaw or Coping Saw

Hammer

Philips Screwdriver (PZ2 size)

Secateurs

Surform Plane

Other

Tape Measure

Rubber Gloves

Pencil

Compass

We recommend having a good read through the following notes before ordering a DIY Kit as there are some materials & tools that may need to be purchased to complete your DIY Polecat so it's prudent to cost & gauge the project beforehand.

We also think it's worth saying that although we have simplified things as much as possible this DIY project may still be too much for an inexperienced DIY'er but that said, nothing ventured, nothing gained.

Overview

The DIY Pack is based on the materials we use in our manufacturing process so if you have to deviate from these you may need to make adjustments in terms of fixings, template measurements & quantities.

Polecats units are constructed from 4mm thick 152mm inside diameter spiral wound cardboard tubes - the tube sizing doesn’t have to be identical to this spec but if you are planning on using a Cat’s Cradle with your DIY Polecat the outside diameter of the tube once wrapped should be close to 180mm.

Essex Tubes supply our cardboard cores in standard 3m lengths & most of our carpet comes from Alternative Flooring, Kersaint Cobb or Crucial Trading but as you would expect non-trade purchases from these companies will be probably be uneconomical in terms of cost so searching your local carpet stores for unwanted tube cores & online for carpet remnants will definitely be worth investigating.

Although we show a cardboard tube in the DIY instructions we think the best DIY option is to use a PVC drain pipe instead of cardboard tube - we actually used a drain pipe for our first prototype back in 2004 & if you use a Metric 160mm soil pipe this will have the same external & internal tube size as our Polecat cardboard tube so you will also have the option of using a Cat’s Cradle on the unit as long as a similar thickness coir to our standard finish is used to wrap the unit i.e. 12-15mm. You can use an Imperial 6” soil pipe but the internal & external dimensions will differ slightly from the Metric version.

Polecat has a wrap-around detail over a one piece 160mm diameter 22mm thick rebated end cap at each end of the unit as standard - this guide shows a three part DIY end cap assembly, which is made up of a round 12mm thick MDF inset disc fixed to two larger 9mm thick MDF discs back fixed to it to form a collar.

If you do end up using a 160mm diameter tube with a 4mm wall the DIY end cap assembly cut a 108mm inset disc with 152mm & 160mm discs to form the collar & allow for the 4mm for the tube wall thickness - this assembly gives a 26mm edge for the coir to be wrapped over & glued onto.

If you use a smaller diameter tube you will need to adjust these dimensions & set out as the 38mm feet & 30mm bush might not work noting that the 26mm wrapped end detail is a minimum in terms of the folding & working the coir material around this edge - there are some work arounds noted in the steps but it’s best to have a plan in place before starting if using a tube diameter less than our standard diameter.

The end cap assembly is fitted with a bush at both ends so you can turn your unit upside down when it becomes worn - the feet can simply be un-screwed & refitted.

Using our DIY Kit the tube needs to be 78mm shorter than your ceiling height so that when the unit is complete you will have a 36mm clearance for installation.

The tube is covered in latex backed coir carpet, which is bonded to the tube using a non-toxic non-flammable adhesive - we use a ready mixed water based flooring adhesive made by Soudal, which comes in 1L & 5L sizes so one or two 1L tubs should be fine for a standard ceiling height.

We've tested lots of different carpet & come to the conclusion (with lots of the help from our cats) that a wide ribbed looped boucle weave that has a 12-15mm span between ribs is best for climbing but you can obviously try out your own materials.

The covering needs to be glued to the post with the ribs running vertically to aid climbing - flooring adhesive is used to bond the covering to the tube but the seam to join the edges of the covering needs to be fixed with a hot melt heated glue gun.

If you don’t have a glue gun there are some reasonably priced mini glue guns available to purchase online but please make sure you purchase additional glue sticks with the gun - you will need between 10-20 of the mini 100mm long sticks for the main seam, end cap fixing & finishing the seam depending on your ceiling height - you can use a contact adhesive in place of the hot melt glue but it will be easier with a glue gun based on our experience & without the strong odours & toxic substances used in contact adhesive.

The carpet is folded around the end of the tube & fixed up to the end cap assembly to give a clean wrapped detail but you can also just cut the carpet at the ends, which is much easier to complete, although you may find it will fray & be prone to much more wear & tear - if you intend to have a straight cut at the end of the tube, rather than a wrapped end detail, you don’t have to bother with the smaller MDF end cap as you can simply mount the bush & feet onto the rebated discs but remember to cut the tube 24mm longer to make up for the inset discs that have been removed.

So, if you've read the above & want to give this DIY project a go roll up your sleeves & the following step-by-step notes should see you through to making your own Polecat.

Step-By-Step Fabrication

Mark-up & cut the tube to length using a tenon or carpentry saw - the tube length needs to be 78mm shorter than your ceiling height & it helps if you have several marked-up points around the tube as a guide when cutting to ensure a straight cut.

Cut-out the MDF end cap assemblies using a jigsaw or coping saw - use a compass to scribe the inset disc & end caps marking up centres for each disc.

Drill the centre holes using the flat wood bit.

Back fix the discs using 3 of the pan head screws for each assembly.

Use the drill bit to line up the discs when screwing them together making sure that you inset the screws at least 30mm from the rebated disc edge

Drill 3 pilot holes for the feet equi spaced around the inset disc- we inset the centre holes 5mm in from the edge of the inset disc so that the 38mm diameter feet sit over the wrapped end seam when installed

Install the bushes (make sure these are the ones that have not been drilled through) into the end caps with a dab of glue gel - it's best to use a rubber mallet but a hammer will also get the job done if you’re careful.

NB as noted in the Overview if you are using a smaller diameter tube than our standard tube the feet & bush layout on the bottom end cap assembly might not work in terms of spacing - to help with the layout spacing you can just install one bush on the bottom end cap assembly but you can still drill the hole to make it upside down future proof.

Scribe a horizontal line along the length of the cut tube - you can rest a pencil on top of MDF off-cut that's half the height of the tube then run it along the length of the tube.

Install the end cap assemblies into the ends of the tube - use 3 u-nails to fix each assembly making sure that you come in 4mm from the end of the tube when fixing

If the end cap assemblies are too tight you can trim back the diameter of the rebated disc using a surform plane.

You can also use the surform plane to clean up the collar edge of the end cap assembly if you are slightly over with the diameter sizing

The carpet needs to be approx 150mm longer than the tube length & 3.3 times wider than the outside tube diameter – use the secateurs to make a clean cut down the long edge of the carpet between the ribs making sure that you leave as much as possible of the flat section between the ribs of the carpet if using a boucle or looped pile material.

Fix the cut edge of the carpet to the tube along the scribed line – use the hot melt glue gun & make sure you have equal overhanging carpet at each end of the tube.

After making sure that the carpet edge is fixed by pressing down along the seam a few times use the carpet adhesive to fix the carpet around the tube - we wear rubber gloves to apply the adhesive as it's easier to work on to the tube than an applicator.

Work the glue on to the tube in sections rotating the tube as you glue leaving a 40-50mm unglued section up to the seam - try to apply a line of ridges along this point to help with fixing the carpet.

Then work the fabric around the tube making sure that there is no give in the carpet & the wrap is as tight as possible - it will be easier working the coir around the tube if you place it on a carpeted floor then massage the coir whilst rotating the tube bit-by-bit as the carpet will will help to hold the wrapped sections tight.

We use clamps at this stage to hold the carpet seam together while working the carpet around the tube & then leave the unit overnight for the glue to cure - it’s unlikely that you will have clamps so you’ll need to continue pulling & wrapping the carpet as noted in the previous stage until the carpet has bonded enough to move onto the next step, which should take around 20 minutes or so.

Trim the edge of the carpet to the glued seam using the secateurs then fix this edge using the hot melt glue gun – it’s best if you can get a clean join without the edges overlapping or being too far apart.

When fixing the seam it's best to apply glue in sections of 10-15cm at a time so that the glue does not harden.

Cut the carpet at each end of the unit using the secateurs to form the wrapped end detail that will fold over the end caps.

Fold the carpet over the ends & use the inside edge of the end cap to guide the secateurs when making a cut.

The carpet will be easier to trim if you remove excess fabric before cutting the flaps but make sure you leave at least 4-5cm to form the flaps.

Cut the flaps between the ribs into sections creating a small v shape cut - we cut the flap into 4 sections but it will be easier if you go for 6-8 as you won’t need to apply as much pressure when forming the wrap.

Fix the flaps with the hot melt glue gun one at a time.

Work the flap on to the end cap making sure the ribs are radiating pointing to the centre of the end end & you have a good fix before moving on to the next one.

Clean up the edge of the wrapped ends with the secateurs.

Screw the feet around the end cap equi distance - it’s best to drill small pilot holes for the screws & the feet can overlap the coir slightly if you need to avoid the central bush.

Pull some coir strands from the carpet off cuts & cut these into 3-4mm long fibres in preparation for finishing the unit's seam.

Apply a thick bead of hot melt glue along the seam then dab these fibres onto the seam - again it's best to apply the glue in sections of 10-15cm at a time.

Stand back & admirer your handy work.

Installation

Please refer to our special DIY Polecat Install for installation instructions.

NB Please note that although we obviously carry stock of the standard tube, carpet & sheeting materials we are unable to sell these materials to customers (sorry) but we do sometimes have offcuts & tubes that are offered up free-of-charge for collection - please sign up to our newsletter below if you would like to hear about these offers.